Supply chains are changing, and it’s never been more important to incorporate warehouse management systems (WMS) into your warehouse operation. Today’s customers expect more and because of the transition to a digital supply chain, warehousing and logistics managers must understand how to choose a warehouse management system that will propel their business to the next level.

How to Choose a Warehouse Management System

Are you ready to learn how to choose the right warehouse software for improved warehouse operations? Here’s all you need to know to choose the WMS system that will give you the best return on investment and improve your business operations.

1. Consider the Timing

Knowing when to add WMS solutions to your warehouse is one of the keys to success, and there is one way to identify when it’s time. If you are continually adding warehouse workers to keep up with demand and ensure customer satisfaction, it’s probably time to get serious about choosing a warehouse management system.

2. Consider Inventory Control

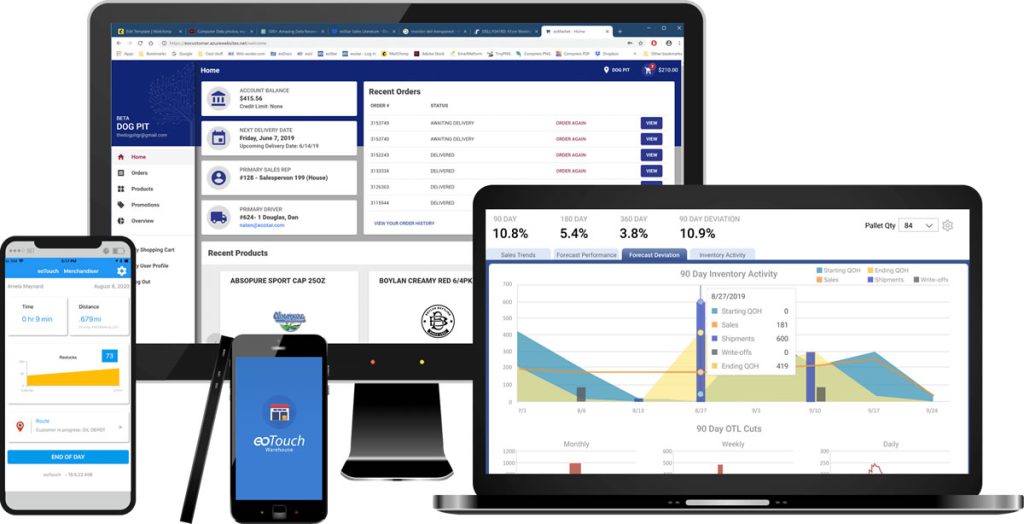

If your inventory isn’t correct and updated in real-time, your customer service abilities will suffer. When choosing a WMS, it’s important to look at products during the selection process that can help wrangle your inventory to make it more manageable. For instance, eoWarehouse records picks in real-time which means your inventory levels will always be accurate.

3. Let the Business Lead the Decision

The IT department is a great help when considering an Enterprise Resource Planning (ERP system), but the party logistics of the entire business model should come into play when making the decision. Many distribution centers make the mistake of allowing IT to lead the decision instead of letting the business lead it.

4. Understand the Costs

When thinking about adding a WMS system, it’s smart to speak with the representative of the software manufacturer to gain an understanding of your needs and what it will cost to get the system up and running. Credible and successful WMS developers are happy to work with you in assessing your needs and budget before asking you to make a purchase.

5. Get Real World Statistics

A lot of companies will speak with you about how much money they can save your company, but you should always ask for specifics. For instance, it’s one thing for a salesperson to tell you that you will experience substantial savings and ROI with their product, and it’s another for them to show you how their product has impacted their existing customers. eoWarehouse, for example, can confidently claim that its customers routinely see a 90% reduction in mispicks and a 39% increase in average cases picked per hour.

6. Think about Seasons

If your distribution business needs to forecast orders seasonally, then you should look for a WMS that offers forecasting as part of its offering. Today’s warehouse managers understand that relying on human calculations to forecast seasonal orders isn’t productive and can easily lead to customer dissatisfaction. Instead, when a WMS system uses historical data to calculate those needs, warehouse managers can relax and know that they will have the right amount of product for the season.

7. Consider Relationship

When purchasing a WMS system, you will establish a relationship with the vendor, and that relationship is an important aspect of how successful you will be with the system. You will rely on the vendor for technical support, assessing your needs before purchasing the system, and ongoing support in training and other areas. When you speak to a vendor during the selection process, be sure to take note of how helpful they are. You should seek to do business with a WMS vendor who will always be responsive to your needs.

8. Think About Growth

When analyzing WMS systems, you should speak to the vendor about how you can use the system as your business continues to grow. Some WMS systems make it difficult to make adjustments to the system as your business grows while others make the process easy. If you plan to grow your business – and who doesn’t? – make sure your warehouse management system can easily grow alongside you.

9. Connectivity is Key

No business operates on an island, and that is especially true for distribution centers. The relationships and connections you have with your suppliers, truckers, and customers are key. You need feedback and information from all of them, and a good warehouse management system can ensure those connections are in place and will contribute to your success. For instance, eoWarehouse ensures that your customers can connect via the system to leave valuable feedback.

Is It Time to Choose Your Warehouse Management System?

If your distribution center is growing and you need a warehouse management system to enhance the growth and ensure that you can continue to provide the best customer service possible, it may be time to begin thinking about adding a WMS system. At eoStar, we are happy to discuss your current operations and show you how we can help you improve your business model. Why not give us a call and let us talk to you about how we can make your job easier – all the while boosting your customer satisfaction?